Characterisation of Battery Components and Materials

T

he

porous

nature

of

battery

components:

anode,

cathode,

separator

and

solid

electrolyte

and

also

the

finished

electrode

architecture

is

critical

to

the performance and optimization of battery systems.

Porous

characteristics

can

be

described

by

pore

volume,

pore

size

distribution,

volume

porosity,

specific

surface

area

and

density.

Together

these

determine

the

selection

of

raw

materials,

the

formulation

of

components,

such

as

binder

properties

and

the

optimal

processing

conditions

for

electrode production.

These

porous

characteristics

also

profoundly

influence

the

performance

of

the

finished

cell.

The

porous

nature

of

the

raw

materials

and

the

production

steps

applied

to

obtaining

the

finished

cell

determine

the

porosity

of

the

cell.

This

in

turn

influences

electrode

conductivity,

energy

density,

charging

efficiency,

electrolyte

transport

characteristics,

cycling

lifetime,

availability

of

electrochemically

active

sites

and

electrode

degradation.

Complete

understanding

of

the

porous

character

of

materials

is,

therefore,

critical

to

all

stages

of

materials

selection,

cell

development

and

electrode processing.

Key Applications – Materials

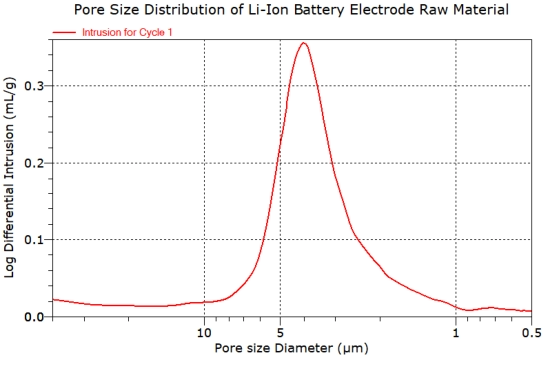

Assessment of porous nature of raw materials for formulation

Quality control of incoming raw materials

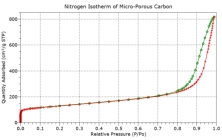

Surface area and porosity of high area carbons & graphites

Surface area and porosity of active cathode material

Characterisation of inter-particulate porosity

Formulation of binder composition and loading

Measurement of absolute, bulk and particle density

Determination of processing conditions

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

ranges

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application

in

a

battery

system.

Combined

with

state-of-the-art

instrumentation

and

software, offering flexible and extensive reporting options, we help to maximise the amount of high quality data describing sample materials.

Key Analytical Techniques

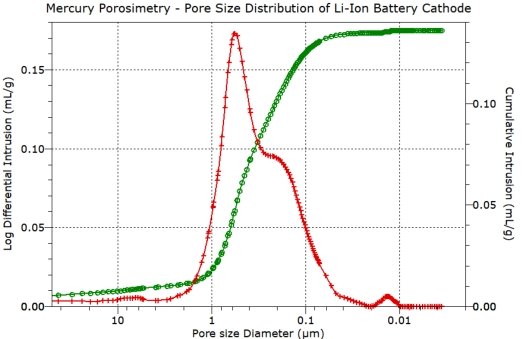

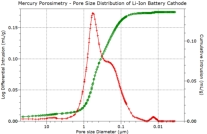

Mercury Porosimetry – Pore Characterisation

Finished anode and cathode

Separator

Raw material components and blends

Pore size and volume characterisation

Volume porosity determination

Permeability and pore tortuosity determination

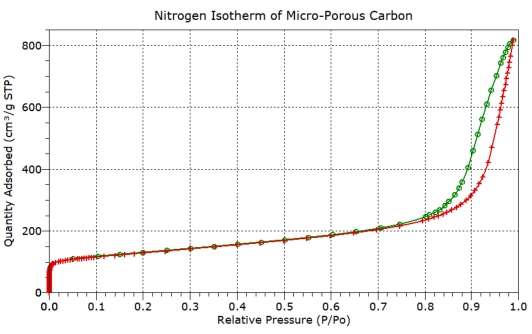

Gas Adsorption

Specific Surface Area (BET Area)

Micropore Analysis of high area constituents

Micropore / Mesopore characterisation

Pore size and volume characterisation

Density Analysis

Particle density of raw materials

Absolute density of raw materials and finished components

Bulk density of raw materials and finished components

The

porous

characteristics

of

finished

electrodes

are

partially

determined

by

the

inter-particulate

porosity

of

the

raw

materials,

porosity

within

raw

material

particles,

binder

material

and

loading

and

the

production

conditions

of

calendaring

and

drying.

This

porosity

exerts

profound

influence

over

electrolyte

transport,

availability

of

electrochemically

active

sites,

charge

and

discharge

efficiency

and

capacity,

and

electrode

and

cycle

lifetime.

Pore

sizes

present

within

electrodes

typically

fall

within

the

range

analysed

by

the

mercury

porosimetry

technique.

This

can

be

extended

to

consider

permeability,

a

useful

comparison

tool

when

considering

fluid

flow

through

a

porous

sample.

This

technique

is

also

applicable to the analysis of separator materials where a tight distribution of pore sizes is demanded for efficient transport properties.

Key Applications – Components

Determination of separator pore size and porosity

Optimisation of slurry composition

Optimisation of calendaring process

Optimisation of drying process

Characterisation of anode porosity

Characterisation of cathode porosity

Direct relationships with electrode performance

Efficiency and capacity

Charge & Discharge performance

Cycle lifetime

Charging characteristics

Electrolyte transport

Understanding

particle

porosity

is

vital

to

the

selection

and

control

of

high

surface

area

components,

such

as

carbons

and

graphites,

as

well

as

monitoring

the

cathode

materials

and

assessing

the

intercalation

procedure.

Full

characterisation

of

inter-particulate

porosity

is

essential

as

this

describes

packing

characteristics

which

in

turn

determine

the

processing

conditions

required

and

the

porosity

within

finished

electrodes.

This

involves fully understanding inter-particulate spaces beyond that suggested by particle size alone.

Tel: 01763 262333

Characterisation of Battery Components and Materials

The

porous

nature

of

battery

components:

anode,

cathode,

separator

and

solid

electrolyte

and

also

the

finished

electrode

architecture

is

critical

to

the

performance

and

optimization

of

battery systems.

Porous

characteristics

can

be

described

by

pore

volume,

pore

size

distribution,

volume

porosity,

specific

surface

area

and

density.

Together

these

determine

the

selection

of

raw

materials,

the

formulation

of

components,

such

as

binder

properties

and

the optimal processing conditions for electrode production.

These

porous

characteristics

also

profoundly

influence

the

performance

of

the

finished

cell.

The

porous

nature

of

the

raw

materials

and

the

production

steps

applied

to

obtaining

the

finished

cell

determine

the

porosity

of

the

cell.

This

in

turn

influences

electrode

conductivity,

energy

density,

charging

efficiency,

electrolyte

transport

characteristics,

cycling

lifetime,

availability

of

electrochemically

active

sites

and

electrode

degradation.

Complete

understanding

of

the

porous

character

of

materials

is,

therefore,

critical

to

all

stages

of

materials

selection,

cell

development and electrode processing.

Key Applications – Materials

Assessment of raw materials for formulation

Quality control of incoming raw materials

Surface area and porosity of high area carbons & graphites

Surface area and porosity of active cathode material

Characterisation of inter-particulate porosity

Formulation of binder composition and loading

Measurement of absolute, bulk and particle density

Determination of processing conditions

Understanding

particle

porosity

is

vital

to

the

selection

and

control

of

high

surface

area

components,

such

as

carbons

and

graphites,

as

well

as

monitoring

the

cathode

materials

and

assessing

the

intercalation

procedure.

Full

characterisation

of

inter-particulate

porosity

is

essential

as

this

describes

packing

characteristics

which

in

turn

determine

the

processing

conditions

required

and

the

porosity

within

finished

electrodes.

This

involves

fully

understanding

inter-particulate

spaces

beyond

that

suggested by particle size alone.

Key Applications – Components

Determination of separator pore size and porosity

Optimisation of slurry composition

Optimisation of calendaring process

Optimisation of drying process

Characterisation of anode porosity

Characterisation of cathode porosity

Direct relationships with electrode performance

Efficiency and capacity

Charge & Discharge performance

Cycle lifetime

Charging characteristics

Electrolyte transport

The

porous

characteristics

of

finished

electrodes

are

partially

determined

by

the

inter-particulate

porosity

of

the

raw

materials,

porosity

within

raw

material

particles,

binder

material

and

loading

and

the

production

conditions

of

calendaring

and

drying.

This

porosity

exerts

profound

influence

over

electrolyte

transport,

availability

of

electrochemically

active

sites,

charge

and

discharge

efficiency

and

capacity,

and

electrode

and

cycle

lifetime.

Pore

sizes

present

within

electrodes

typically

fall

within

the

range

analysed

by

the

mercury

porosimetry

technique.

This

can

be

extended

to

consider

permeability,

a

useful

comparison

tool

when

considering

fluid

flow

through

a

porous

sample.

This

technique

is

also

applicable

to

the

analysis

of

separator

materials

where

a

tight

distribution

of

pore

sizes

is

demanded

for

efficient

transport

properties.

Key Analytical Techniques

Mercury Porosimetry – Pore Characterisation

Finished anode and cathode

Separator

Raw material components and blends

Pore size and volume characterisation

Volume porosity determination

Permeability and pore tortuosity determination

Gas Adsorption

Specific Surface Area (BET Area)

Micropore Analysis of high area constituents

Micropore / Mesopore characterisation

Pore size and volume characterisation

Density Analysis

Particle density of raw materials

Absolute density of raw materials and finished components

Bulk density of raw materials and finished components

MCA

Services

offers

a

complete

suite

of

techniques

for

the

characterisation

of

material

porosity

throughout

the

ranges

of

micropores,

through

mesopores

and

macropores.

We

also

have

extensive

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results,

relating

porous

characteristics

to

the

sample

material

and

its

ultimate

application

in

a

battery

system.

Combined

with

state-of-the-art

instrumentation

and

software,

offering

flexible

and

extensive

reporting

options,

we

help

to

maximise

the

amount

of

high

quality

data

describing

sample

materials.