Tel: 01763 262333

Porosimetry by Gas Adsorption

Mesopore and Macropore Size, Volume & Area Measurement

The

porous

nature

of

materials

affects

a

wide

variety

of

performance

aspects

in

many

applications,

such

as

adsorption

capacity,

chemical

reactivity,

electrochemical

activity,

structural

properties

and

dissolution

rates.

Understanding

the

components

of

porosity:

pore

volume,

pore

size

and

pore

area,

is,

therefore,

critical

to

many

sectors,

for

example

catalysis,

adsorption

technology,

pharmaceuticals,

energy

generation

and

green

technology.

The

porous

nature

of

materials

includes

the

description

of

several

characteristics

covering

a

wide

range

of

pore

sizes

and

geometries

and

our

porosimetry

page

gives

more

details

of

this.

Mesopores

and

small

macropores

are

conveniently

studied

by

the

analytical

technique

of

gas

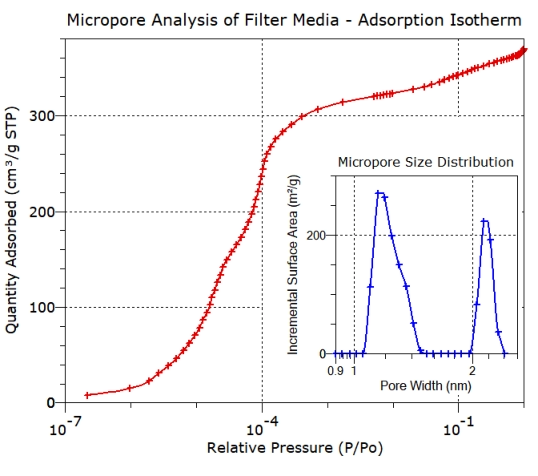

adsorption. This can be extended to include dedicated micropore analysis which is discussed on our Micropore Analysis pages.

Gas

adsorption

provides

pore

volume,

area

and

size

data

in

the

typical

pore

size

range

2

–

300

nm,

although

the

upper

limit

depends

on

the

nature

of

the

sample.

The

latest,

powerful

and

adaptable

instrumentation

combined

with

our

decades

of

experience

means

that

we

can

recommend

the

most

suitable

analytical

options

for

your

samples.

Analyses

and

reporting

options

can

be

tailored

to

provide

the

most

pertinent

information

to

describe

your

particular

samples

and

specific

application.

We

are

also

happy

to

assist

with

data

interpretation

to

ensure

that

you

obtain the most relevant data and information.

Key Applications

Adsorption capacity and efficacy of adsorbates and filter media

Activity of catalysts and catalytic processes

Assessment of new, spent and regenerated catalysts

Assessment of new, spent and regenerated and filter media

Electrochemical activity of battery components and constituents

Fabrication process development and control

Availability of biologically available sites in pharmaceuticals

Inorganics, aluminas and silicas: material assessment

Behaviour of powder materials for pastes and emulsions

Raw material selection and QC process

Dissolution and dispersion assessment and control

Rapid assessment of microporous materials

Analytical Options and Highlights

Pore volume, area and size distributions

Numerically and graphical representations

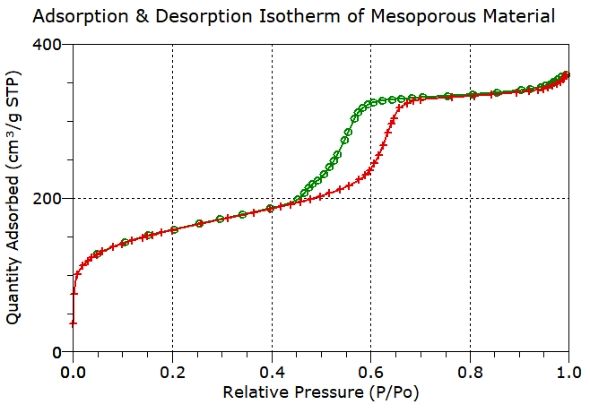

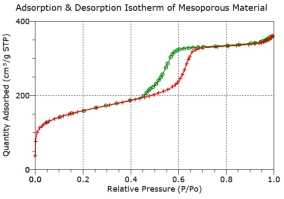

Full gas adsorption and desorption isotherm measurement

Determination of pore geometry

BET Specific Surface Area included

Assessment of microporosity via t-plot analysis

Extensive and flexible analytical and reporting options

Extensive and flexible sample degassing options

Availability of alternative adsorbents: argon and carbon dioxide

Comprehensive range of data reduction options

BET Surface Area

BJH Mesopore volume, area and size – adsorption isotherm

BJH Mesopore volume, area and size – desorption isotherm

t-plot and α-S plot methods

Langmuir Surface Area

Assessment of pore geometry from isotherm hysteresis

Combination with mercury porosimetry: pore size range to 650 µm

The

measurement

of

the

full

gas

adsorption

and

desorption

isotherm

provides

a

full

porosimetry

analysis

technique

for

the

determination

of

pore

volume,

pore

area

and

pore

size

in

the

pore

size

range

2

–

300

nm

diameter,

although

the

upper

range

does

depend

on

the

isotherm

profile

as

dictated

by

the

porous

nature

of

the

sample.

Nitrogen

is

an

ideal

adsorbate,

providing

full

characterisation

throughout

the

mesopore

range

and

into

the

small

macropore

region.

Calculation

of

BET

surface

area

is

included

and

the

assessment

of

the

extent

and

volume

of

microporosity

can

also

be

included

through

specifically

tailored

analytical

conditions.

It

is,

therefore,

a

convenient

and

cost

effective

screening

technique

for

the

evaluation of microporous materials. More extensive micropore analysis is offered via our other dedicated gas adsorption options.

At

MCA

Services

sample

analysis

is

undertaken

using

our

Micromeritics

TriStar

3030

plus

instrument,

which

utilises

the

volumetric

method

of

gas

adsorption.

Before

analysis

it

is

essential

that

samples

are

fully

dried

and

degassed

as

extraneous

substances

will

provide

an

artificially

low

surface

area

value.

We

have

a

comprehensive

range

of

degassing

options,

capable

of

temperatures

in

the

range

ambient

to

400

°C

under

dynamic

vacuum

or

flowing

inert

gas.

We

can,

therefore,

prepare

virtually

any

sample

material

on-site

immediately

prior

to

analysis,

which

ensures the most accurate and reliable measurements are obtained.

At

MCA

Services

we

have

decades

of

experience

in

the

analysis

and

characterisation

of

materials

and

are

always

happy

to

discuss

specific

samples

and

applications.

Our

expertise

ensures

that

the

most

appropriate

analytical

test,

or

combination

of

tests,

are

selected

for

your

particular

sample,

application

and

requirements.

We

also

provide

assistance

with

the

interpretation

of

results

and

more

information

about

these

analytical

options and the background operation and theory can be found on our YouTube channel.

MCA Services

01763 262333

Analytical Options and Highlights

Pore volume, area and size distributions

Numerical and graphical representations

Full gas adsorption and desorption isotherm measurement

Determination of pore geometry

BET Specific Surface Area included

Assessment of microporosity via t-plot analysis

Extensive and flexible analytical and reporting options

Extensive and flexible sample degassing options

Alternative adsorbents: argon and carbon dioxide

Comprehensive range of data reduction options

BET Surface Area

BJH Mesopore volume, area and size

Adsorption and desorption isotherm data

t-plot and α-S plot methods

Langmuir Surface Area

Assessment of pore geometry from isotherm hysteresis

Combination with mercury porosimetry: pore sizes of 650 µm

The

measurement

of

the

full

gas

adsorption

and

desorption

isotherm

provides

a

full

porosimetry

analysis

technique

for

the

determination

of

pore

volume,

pore

area

and

pore

size

in

the

pore

size

range

2

–

300

nm

diameter,

although

the

upper

range

does

depend

on

the

isotherm

profile

as

dictated

by

the

porous

nature

of

the

sample.

Nitrogen

is

an

ideal

adsorbate,

providing

full

characterisation

throughout

the

mesopore

range

and

into

the

small

macropore

region.

Calculation

of

BET

surface

area

is

included

and

the

assessment

of

the

extent

and

volume

of

microporosity

can

also

be

included

through

specifically

tailored

analytical

conditions.

It

is,

therefore,

a

convenient

and

cost

effective

screening

technique

for

the

evaluation

of

microporous

materials.

More

extensive

micropore

analysis

is

offered

via

our

other dedicated gas adsorption options.

Porosimetry by Gas Adsorption

Mesopore and Macropore Size, Volume & Area Measurement

The

porous

nature

of

materials

affects

a

wide

variety

of

performance

aspects

in

many

applications,

such

as

adsorption

capacity,

chemical

reactivity,

electrochemical

activity,

structural

properties

and

dissolution

rates.

Understanding

the

components

of

porosity:

pore

volume,

pore

size

and

pore

area,

is,

therefore,

critical

to

many

sectors,

for

example

catalysis,

adsorption

technology,

pharmaceuticals,

energy

generation

and

green

technology.

The

porous

nature

of

materials

includes

the

description

of

several

characteristics

covering

a

wide

range

of

pore

sizes

and

geometries

and

our

porosimetry

page

gives

more

details

of

this.

Mesopores

and

small

macropores

are

conveniently

studied

by

the

analytical

technique

of

gas

adsorption.

This

can

be

extended

to

include

dedicated

micropore

analysis

which

is

discussed

on

our

Micropore Analysis pages.

Gas

adsorption

provides

pore

volume,

area

and

size

data

in

the

typical

pore

size

range

2

–

300

nm,

although

the

upper

limit

depends

on

the

nature

of

the

sample.

The

latest,

powerful

and

adaptable

instrumentation

combined

with

our

decades

of

experience

means

that

we

can

recommend

the

most

suitable

analytical

options

for

your

samples.

Analyses

and

reporting

options

can

be

tailored

to

provide

the

most

pertinent

information

to

describe

your

particular

samples

and

specific

application.

We

are

also

happy

to

assist

with

data

interpretation

to

ensure

that

you obtain the most relevant data and information.

Key Applications

Adsorption capacity and efficacy of adsorbates

Adsorption capacity and efficacy of filter media

Activity of catalysts and catalytic processes

Assessment of new, spent and regenerated catalysts

Electrochemical activity of battery components

Fabrication process development and control

Availability of biologically active sites in pharmaceuticals

Inorganics, aluminas and silicas

Behaviour of powder materials for pastes and emulsions

Raw material selection and QC process

Dissolution and dispersion assessment and control

Rapid assessment of microporous materials

At

MCA

Services

sample

analysis

is

undertaken

using

our

Micromeritics

TriStar

3030

plus

instrument,

which

utilises

the

volumetric

method

of

gas

adsorption.

Before

analysis

it

is

essential

that

samples

are

fully

dried

and

degassed

as

extraneous

substances

will

provide

an

artificially

low

surface

area

value.

We

have

a

comprehensive

range

of

degassing

options,

capable

of

temperatures

in

the

range

ambient

to

400

°C

under

dynamic

vacuum

or

flowing

inert

gas.

We

can,

therefore,

prepare

virtually

any

sample

material

on-site

immediately

prior

to

analysis,

which

ensures

the

most

accurate

and

reliable

measurements are obtained.

At

MCA

Services

we

have

decades

of

experience

in

the

analysis

and

characterisation

of

materials

and

are

always

happy

to

discuss

specific

samples

and

applications.

Our

expertise

ensures

that

the

most

appropriate

analytical

test,

or

combination

of

tests,

are

selected

for

your

particular

sample,

application

and

requirements.

We

also

provide

assistance

with

the

interpretation

of

results

and

more

information

about

these

analytical

options

and

the

background

operation

and

theory

can

be

found

on

our

YouTube channel.