Tel: 01763 262333

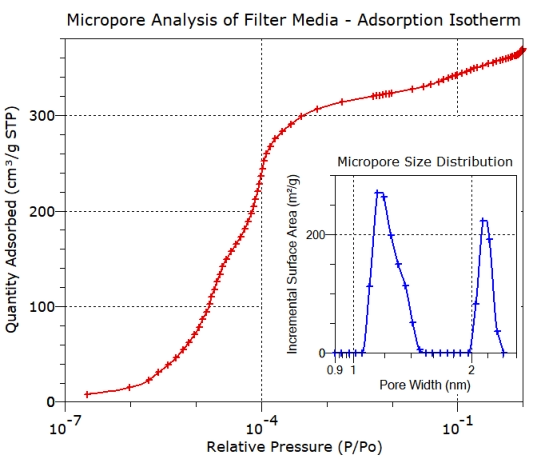

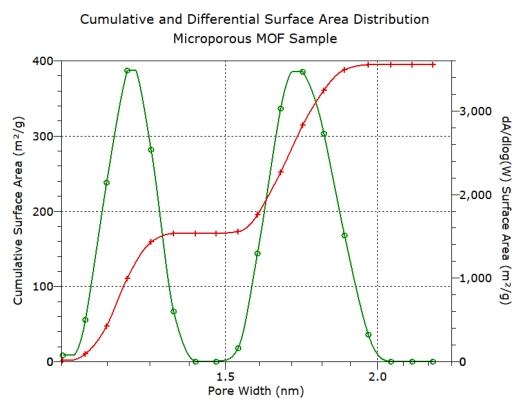

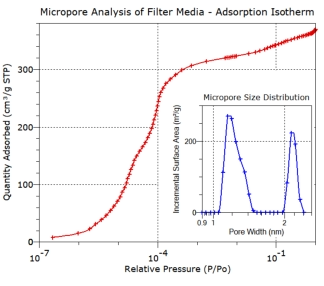

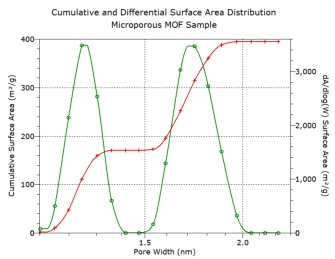

Micropore Analysis

Pore Size Distribution, Pore Volume and Pore Area: Pores < 2nm diameter.

Micropores

are

generally

defined

as

those

smaller

than

2nm

diameter

and

are

common

in

a

range

of

materials.

For

example

carbons

and

nanotubes,

zeolites,

metal

organic

frameworks

(MOFs),

zeolitic

imidazolate

frameworks

(ZIFs),

covalent

organic

frameworks

(COFs)

etc.

Micropores

are

fundamentally

important

to

the

functionality

and

performance

of

many

applications,

such

as

battery

materials,

adsorbents

and

filters,

catalysts,

gas

storage

and

sequestration

materials.

Together,

micropore

volume,

area

and

size

directly

affect

performance

through

determining

capacity,

accessibility,

availability

of

active

sites

and

functionality.

For

many

applications

a

certain

micropore

size

range

is

demanded

in

order

to

maximise

performance.

If

pores

are

too

large

or

too

small

the

material

can

suffer

from

loss

of

capacity

and

activity

through

poor

retention

or

pore

blocking.

A

full

understanding

of

micropore

size,

area

and

volume

is,

therefore,

often

required.

At

MCA

Services

we

offer

a

range

of

micropore

characterisation

options.

Crucially,

dedicated

micropore

analysis

provides

a

full

set

of

pore

size,

volume

and

area

distribution

data

derived

from

specialised

data

reduction

methods,

such

as

DFT

(Density

Functional

Theory)

and

NL-DFT

(Non-Local

Density

Functional

Theory).

These

provide

consioderably

more

information

than

statistical

methods

such as t-plot, αS-plot and the Dubinin models. The can, however, also be applied if required to compare analyses with historical data.

Key Applications

Micropore size distribution, volume and pore area for:

Adsorbent capacity, accessibility and retention

Sequestration capacity, accessibility and retention

Gas storage capacity, accessibility and retention

Catalyst efficiency and activity

Battery efficiency, activity and charge & discharge ability

Filter efficiency and efficacy

Determination of regeneration conditions and efficiency

Investigations of atypical performance:

effects of low capacity and retention

Investigations of product failure: pore blocking

Identification of optimum characteristics and selection of materials

Determination of production and fabrication conditions

At

MCA

Services

we

use

the

latest,

state-of-the-art

Micromeritics

3Flex

instrument

for

micropore

analysis,

choosing

from

a

range

of

available

adsorbate

gases

and

applying

the

volumetric

method

for

the

measurement

of

adsorption

isotherms.

Analyses

can

be

confined

to

the

micropore

region,

typically

<

0.2

relative

pressure,

or

with

many

adsorbates,

extended

to

measure

data

in

the

mesopore

region.

Combined

micropore

and

mesopore

analyses

are,

therefore,

possible

in

a

single

analysis

and

extensive

data

reduction

and

reporting

methods

can

be

employed

to

characterise

each.

Nitrogen

is

most

commonly

used

as

the

adsorbate

with

excellent

results.

However,

when

unfavourable

interactions

between

nitrogen and the sample surface are likely, it is preferable to select an alternative adsorbate, such as argon.

Analytical Options and Highlights

Micropore size distribution (graphical and numerical data)

Micropore area distribution (graphical and numerical data)

Micropore volume distribution (graphical and numerical data)

BET Surface Area included in reports

Extension to full isotherms (< 2nm to ~300nm pore diameter)

Combined micropore and mesopore characterisation

Data reduction by DFT and NL-DFT

Statistical data reduction methods (t-plot, αS-plot, Dubinin methods)

Wide choice of adsorbates: N

2

, Ar, CO

2

, O

2

, H

2

, CO etc

Comprehensive degassing options

The

Micromeritics

3Flex

is

an

extremely

powerful

instrument

with

cutting

edge

technology

and

a

wealth

of

information

can

be

obtained

from

comprehensive

data

reduction

software.

Combined

with

our

decades

of

experience

the

maximum

information

about

your

samples

can

be

obtained

from

a

single

analysis.

At

MCA

Services

we

are

always

happy

to

advise

the

best

analytical

option

for

your

particular

samples,

applications

and

requirements.

We

also

routinely

assist

in

data

interpretation:

selecting

the

most

pertinent

reporting

data

and

relating

porous

characteristics to your specific materials and requirements.

Micropore Analysis

Pore Size Distribution, Pore Volume and Pore Area: Pores < 2nm diameter.

Micropores

are

generally

defined

as

those

smaller

than

2nm

diameter

and

are

common

in

a

range

of

materials.

For

example

carbons

and

nanotubes,

zeolites,

metal

organic

frameworks

(MOFs),

zeolitic

imidazolate

frameworks

(ZIFs),

covalent

organic

frameworks

(COFs)

etc.

Micropores

are

fundamentally

important

to

the

functionality

and

performance

of

many

applications,

such

as

battery

materials,

adsorbents

and

filters,

catalysts,

gas

storage

and

sequestration

materials.

Together,

micropore

volume,

area

and

size

directly

affect

performance

through

determining

capacity,

accessibility,

availability

of

active

sites

and

functionality.

For

many

applications

a

certain

micropore

size

range

is

demanded

in

order

to

maximise

performance.

If

pores

are

too

large

or

too

small

the

material

can

suffer

from

loss

of

capacity

and

activity

through

poor

retention

or

pore

blocking.

A

full

understanding

of

micropore

size,

area

and

volume

is,

therefore,

often

required.

At

MCA

Services

we

offer

a

range

of

micropore

characterisation

options.

Crucially,

dedicated

micropore

analysis

provides

a

full

set

of

pore

size,

volume

and

area

distribution

data

derived

from

specialised

data

reduction

methods,

such

as

DFT

(Density

Functional

Theory)

and

NL-DFT

(Non-Local

Density

Functional

Theory).

These

provide

consioderably

more

information

than

statistical

methods

such as t-plot, αS-plot and the Dubinin models. The can, however, also be applied if required to compare analyses with historical data.

Micropore Analysis

Pore Size Distribution, Pore Volume and Pore Area: Pores < 2nm diameter.

Micropores

are

generally

defined

as

those

smaller

than

2nm

diameter

and

are

common

in

a

range

of

materials.

For

example

carbons

and

nanotubes,

zeolites,

metal

organic

frameworks

(MOFs),

zeolitic

imidazolate

frameworks

(ZIFs),

covalent

organic

frameworks

(COFs)

etc.

Micropores

are

fundamentally

important

to

the

functionality

and

performance

of

many

applications,

such

as

battery

materials,

adsorbents

and

filters,

catalysts,

gas

storage

and

sequestration

materials.

Together,

micropore

volume,

area

and

size

directly

affect

performance

through

determining

capacity,

accessibility,

availability

of

active

sites

and

functionality.

For

many

applications

a

certain

micropore

size

range

is

demanded

in

order

to

maximise

performance.

If

pores

are

too

large

or

too

small

the

material

can

suffer

from

loss

of

capacity

and

activity

through

poor

retention

or

pore

blocking.

A

full

understanding

of

micropore

size,

area

and

volume

is,

therefore,

often

required.

At

MCA

Services

we

offer

a

range

of

micropore

characterisation

options.

Crucially,

dedicated

micropore

analysis

provides

a

full

set

of

pore

size,

volume

and

area

distribution

data

derived

from

specialised

data

reduction

methods,

such

as

DFT

(Density

Functional

Theory)

and

NL-DFT

(Non-Local

Density

Functional

Theory).

These

provide

considerably

more

information

than

statistical

methods

such

as

t-plot,

αS-plot

and

the

Dubinin

models.

The

can,

however, also be applied if required to compare analyses with historical data.

Micropore Analysis

Pore Size Distribution, Pore Volume and Pore Area

Pores < 2nm diameter

Micropores

are

generally

defined

as

those

smaller

than

2nm

diameter

and

are

common

in

a

range

of

materials.

For

example

carbons

and

nanotubes,

zeolites,

metal

organic

frameworks

(MOFs),

zeolitic

imidazolate

frameworks

(ZIFs),

covalent

organic

frameworks

(COFs)

etc.

Micropores

are

fundamentally

important

to

the

functionality

and

performance

of

many

applications,

such

as

battery

materials,

adsorbents

and

filters,

catalysts,

gas

storage

and

sequestration

materials.

Together,

micropore

volume,

area

and

size

directly

affect

performance

through

determining

capacity,

accessibility,

availability

of

active

sites

and

functionality.

For

many

applications

a

certain

micropore

size

range

is

demanded

in

order

to

maximise

performance.

If

pores

are

too

large

or

too

small

the

material

can

suffer

from

loss

of

capacity

and

activity

through

poor

retention

or

pore

blocking.

A

full

understanding

of

micropore

size,

area

and

volume

is,

therefore,

often

required.

At

MCA

Services

we

offer

a

range

of

micropore

characterisation

options.

Crucially,

dedicated

micropore

analysis

provides

a

full

set

of

pore

size,

volume

and

area

distribution

data

derived

from

specialised

data

reduction

methods,

such

as

DFT

(Density

Functional

Theory)

and

NL-DFT

(Non-Local

Density

Functional

Theory).

These

provide

considerably

more

information

than

statistical

methods

such

as

t-plot,

αS-plot

and

the

Dubinin

models.

The

can,

however,

also

be

applied

if

required

to

compare

analyses with historical data.

Key Applications

Micropore size distribution, volume and pore area for:

Adsorbent capacity, accessibility and retention

Sequestration capacity, accessibility and retention

Gas storage capacity, accessibility and retention

Catalyst efficiency and activity

Battery efficiency, activity and charge / discharge ability

Filter efficiency and efficacy

Determination of regeneration conditions and efficiency

Investigations of atypical performance:

effects of low capacity and retention

Investigations of product failure: pore blocking

Identification of optimum characteristics and selection of materials

Determina

tion of production and fabrication conditions

Analytical Options and Highlights

Micropore size distribution (graphical and numerical data)

Micropore area distribution (graphical and numerical data)

Micropore volume distribution (graphical and numerical data)

BET Surface Area included in reports

Extension to full isotherm (< 2nm to ~300nm pore diameter)

Combined micropore and mesopore characterisation

Data reduction by DFT and NL-DFT

Statistical data reduction (t-plot, αS-plot, Dubinin methods)

Wide choice of adsorbates: N

2

, Ar, CO

2

, O

2

, H

2

, CO etc

Comprehensive degassing options

The

Micromeritics

3Flex

is

an

extremely

powerful

instrument

with

cutting

edge

technology

and

a

wealth

of

information

can

be

obtained

from

comprehensive

data

reduction

software.

Combined

with

our

decades

of

experience

the

maximum

information

about

your

samples

can

be

obtained

from

a

single

analysis.

At

MCA

Services

we

are

always

happy

to

advise

the

best

analytical

option

for

your

particular

samples,

applications

and

requirements.

We

also

routinely

assist

in

data

interpretation:

selecting

the

most

pertinent

reporting

data

and

relating

porous

characteristics

to

your specific materials and requirements.