Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End, Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

Additive Manufacturing / 3D Printing Materials

Additive

manufacturing,

also

known

as

3D

printing,

is

growing

at

an

amazingly

fast

rate

and

presents

exciting

new

opportunities

in

an

incredibly

diverse range of applications and industries.

The

porosity

of

raw

materials

significantly

influences

manufacturing

parameters:

the

size

and

volume

of

inter-particle

void

spaces,

related

to

particle

size

and

shape,

determine

the

physical

packing

of

a

powder

bed

and

In

turn,

this

will

determine

manufacturing

conditions

and

effect

the physical properties and appearance of finished articles.

Key Points:

•

Characterisation of raw materials to determine manufacturing conditions

•

BET Surface Area is critical to raw material specifications

•

BET Surface Area influences the sintering process

•

Determination of particulate void space and particle packing

•

Characterisation of finished pieces for porosity

•

Porosity effects mechanical strength, hardness and finish quality

•

Introducing porosity is necessary for reducing weight

•

Pore size and volume is critical to matching architectures & scaffolds

•

Porosity is also critical to the weight / strength balance

•

Assistance with data interpretation

•

Expansive data presentation and comparative overlay options

A

range

of

techniques

are

available

for

the

characterisation

of

both

raw

materials

and

finished

articles

and

these

can

be

applied

to

a

very

wide

range

of

materials:

including

thermo-plastics,

metals,

alloys,

glass

and

biomedical

materials.

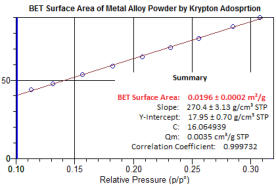

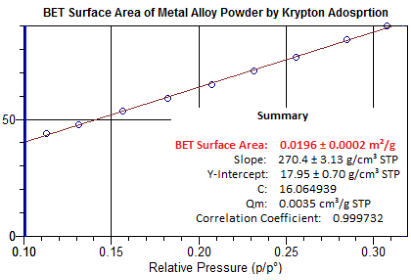

BET

Surface

Area

can

be

applied

to

the

determination

of

printing

conditions

as

it

influences

particle

sintering.

Many

materials

used

in

additive

manufacturing

are

of

low

surface

area,

such

as

thermoplastics

and

metal

powders,

and

at

MCA

Services

we

offer

BET

Surface

area

determination

by

krypton

adsorption

which

is particularly suited to these materials.

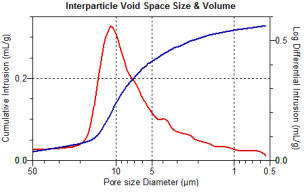

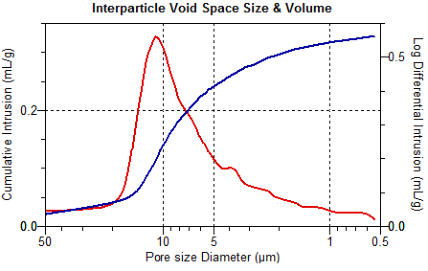

Mercury

porosimetry

is

used

for

the

determination

of

pore

volume,

pore

size

distribution

and

volume

porosity

over

a

wide

range

of

pore

sizes.

For

raw

materials

this

can

be

applied

to

the

characterisation

of

inter-particle

void

spaces,

related

to

particle

packing,

and

provides

complimentary

information

to

particle

size

and

shape

analysis.

Mercury

porosimetry

can

also

be

applied

to

finished

articles

and

becomes

important

since

porosity

effects

physical

properties:

such

as

mechanical

strength,

hardness

and

the

anesthetic

quality

of

the

surface

finish.

In

some

applications,

for

example

bio-medical,

it

is

critical

to

match

the

porous

nature

of

the

manufactured

article

with

the

existing

support

material.

Mercury

porosimetry

is

particularly

useful

as

it

provides

a

full

characterisation

of

pore

volume

and

pore

size

distribution

as

well

as

the measurement of volume porosity.

MCA

Services

also

offers

the

measurement

of

bulk

density,

absolute

density

and

skeletal

density

via

our

mercury

pycnometry

and

helium

pycnometry

options.

The

density

of

both

raw

materials

and

finished

articles

is

often

part

of

the

specification

parameters

and

combination

of

bulk

and

skeletal

densities

can

be

applied

to

the

determination

of

Total

Pore

Volume.

Deviation

from

theoretical

density

can

be

applied

to

the determination of blind pore

Key Techniques

•

Analysis of powders, granules and finished pieces

•

BET Surface Area - including krypton adsorption for low area materials

•

Mercury Porosimetry - pore size, pore volume & pore area distribution

•

Mercury Porosimetry - characterisation of particle packing / void space

•

Permeability and Tortuosity measurement via Mercury Porosimetry

•

Gas Adsorption - pore size, area & volume distribution of mesopores

•

Density measurement - absolute density, bulk density & skeletal density

•

Measurement of Total Pore Volume

Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End,

Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

01763262333

Additive Manufacturing / 3D Printing Materials

Additive manufacturing, also known as 3D printing, is growing at an

amazingly fast rate and presents exciting new opportunities in an

incredibly diverse range of applications and industries.

The porosity of raw materials significantly influences manufacturing

parameters: the size and volume of inter-particle void spaces, related to

particle size and shape, determine the physical packing of a powder

bed and In turn, this will determine manufacturing conditions and effect

the physical properties and appearance of finished articles.

Key Points:

•

Characterisation

of

raw

materials

to

determine

manufacturing

conditions

•

BET Surface Area is critical to raw material specifications

•

BET Surface Area influences the sintering process

•

Determination of particulate void space and particle packing

•

Characterisation of finished pieces for porosity

•

Porosity effects mechanical strength, hardness and finish quality

•

Introducing porosity is necessary for reducing weight

•

Pore

size

and

volume

is

critical

to

matching

architectures

&

scaffolds

•

Porosity is also critical to the weight / strength balance

•

Assistance with data interpretation

•

Expansiv

e data presentation and comparative overlay options

A range of techniques are available for the characterisation of both raw

materials and finished articles and these can be applied to a very

wide range of materials: including thermo-plastics, metals, alloys,

glass and biomedical materials. BET Surface Area can be applied to

the determination of printing conditions as it influences particle

sintering. Many materials used in additive manufacturing are of low

surface area, such as thermoplastics and metal powders, and at

MCA Services we offer BET Surface area determination by krypton

adsorption which is particularly suited to these materials.

Mercury porosimetry is used for the determination of pore volume,

pore size distribution and volume porosity over a wide range of pore

sizes. For raw materials this can be applied to the characterisation of

inter-particle void spaces, related to particle packing, and provides

complimentary information to particle size and shape analysis.

Mercury porosimetry can also be applied to finished articles and

becomes important since porosity effects physical properties: such

as mechanical strength, hardness and the anesthetic quality of the

surface finish. In some applications, for example bio-medical, it is

critical to match the porous nature of the manufactured article with

the existing support material. Mercury porosimetry is particularly

useful as it provides a full characterisation of pore volume and pore

size distribution as well as the measurement of volume porosity.

MCA Services also offers the measurement of bulk density, absolute

density and skeletal density via our mercury pycnometry and helium

pycnometry options. The density of both raw materials and finished

articles is often part of the specification parameters and

combination of bulk and skeletal densities can be applied to the

determination of Total Pore Volume. Deviation from theoretical

density can be applied to the determination of blind pore

Key Techniques

•

Analysis of powders, granules and finished pieces

•

BET Surface Area - including krypton adsorption for low area

materials

•

Mercury Porosimetry - pore size, pore volume & pore area

distribution

•

Mercury Porosimetry - characterisation of particle packing / void

space

•

Permeability and Tortuosity measurement via Mercury

Porosimetry

•

Gas Adsorption - pore size, area & volume distribution of

mesopores

•

Density measurement - absolute density, bulk density & skeletal

density

•

Measurement of Total Pore Volume