Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End, Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

PHARMACEUTICAL ANALYSIS AT MCA SERVICES

The

physical

characteristics

of

pharmaceutical

forms

are

often

critical

to

their

ultimate

effectiveness.

Knowledge,

understanding

and

control

of

physical

properties

is

fundamentally

important

to

every

phase

of

pharmaceutical

formulation,

evaluation,

production

and

QC.

Quantification

of

physical

properties are often classified as being critical within a QbD framework.

The

porous

characteristics

of

pharmaceuticals

in

many

forms,

such

as

APIs,

excipients,

powder

blends,

granules

and

solid

dosages

are

influential

to

pharmaceutical

performance

and

efficiency

and

have

direct

effects

on

dissolution

rate,

solubility,

tablet

strength

and

hardness,

long

term

stability

and

shelf-life.

Key Benefits:

•

Assessment of API and excipient materials

•

Analysis of many pharmaceutical forms

•

Investigation of batch failures

•

Investigation of batch-to-batch variability

•

Determination of long-term stability & shelf-life

•

Identification of counterfeit pharmaceuticals

•

Data interpretation included as standard

•

All analyses undertaken to ISO 17025:2017

•

Adaptable to different test methods

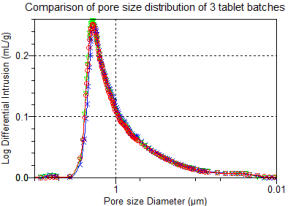

Measurement

of

specific

surface

area

(SSA),

pore

volume,

average

pore

size

and

pore

size

distribution

provides

essential

information

for

the

characterisation

of

the

porous

nature

of

pharmaceuticals.

Porosity

within

pharmaceutical

materials

can

be

present

in

various

locations:

within

tablet

cores

and

coatings,

granules,

pre-cursor

power

blend

particles

as

well

as

the

inter-particle

voids

within

powder

blends.

All

have

profound

effects

on

pharmaceutical

efficiency

and

the

characterisation

of

powder

blends

allows

for

predictions

of

the

solid

dosage

form

to

be

made

and

for

variability

to

be

traced.

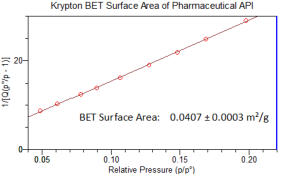

Gas

Adsorption

is

typically

used

for

SSA

measurement,

using

either

nitrogen

or

krypton

adsorption.

Mercury

Porosimetry

is

used

for

the

full

characterisation of pore volume and pore size and is more informative than SSA by gas adsorption data alone.

Key Techniques:

•

BET surface area (SSA) by nitrogen

•

BET surface area (SSA) by krypton for low area samples

•

Mercury Porosimetry for pore volume measurement

•

Mercury Porosimetry for pore size distribution

•

Mercury Porosimetry for volume (%) porosity measurement

•

Micropore analysis for pore volume, area and size measurement

•

Bulk (envelope) density measurement

•

Analysis of powder blends

•

Analysis of solid dosage forms

At

MCA

Services

we

offer

a

complete

suite

of

techniques

for

the

characterisation

of

sample

porosity

with

the

experience

and

expertise

to

actively

assist

with

the

interpretation

of

results

and

their

relation

to

development

and

performance

criteria.

Our

ongoing

in-house

research

continues

to

highlight

the

significance of and application of these analytical techniques to the pharmaceutical sector.

LATEST RESEARCH NEWS:

New research paper by MCA Services in International Journal of Pharmaceutics

BET surface area measurement of commercial magnesium stearate by krypton adsorption in preference to

nitrogen adsorption. International Journal of Pharmaceutics. Volume 568, 10 September 2019.

Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End,

Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

PHARMACEUTICAL ANALYSIS

The physical characteristics of pharmaceutical forms are often critical to

their ultimate effectiveness. Knowledge, understanding and control of

physical properties is fundamentally important to every phase of

pharmaceutical formulation, evaluation, production and QC. Quantification

of physical properties are often classified as being critical within a QbD

framework.

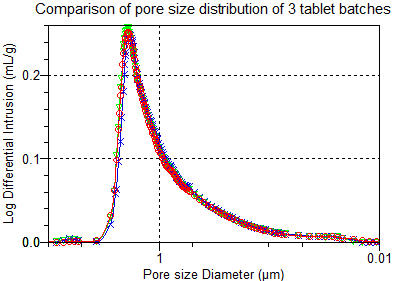

The porous characteristics of pharmaceuticals in many forms, such as APIs,

excipients, powder blends, granules and solid dosages are influential to

pharmaceutical performance and efficiency and have direct effects on

dissolution rate, solubility, tablet strength and hardness, long term stability

and shelf-life.

Key Benefits:

•

Assessment of API and excipient materials

•

Analysis of many pharmaceutical forms

•

Investigation of batch failures

•

Investigation of batch-to-batch variability

•

Determination of long-term stability & shelf-life

•

Identification of counterfeit pharmaceuticals

•

Data interpretation included as standard

•

All analyses undertaken to ISO 17025:2017

•

Adaptable to different test methods

Measurement of specific surface area (SSA), pore volume, average pore size

and pore size distribution provides essential information for the

characterisation of the porous nature of pharmaceuticals. Porosity within

pharmaceutical materials can be present in various locations: within tablet

cores and coatings, granules, pre-cursor power blend particles as well as

the inter-particle voids within powder blends. All have profound effects on

pharmaceutical efficiency and the characterisation of powder blends allows

for predictions of the solid dosage form to be made and for variability to be

traced.

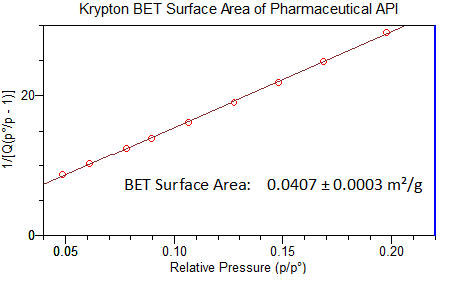

Gas Adsorption is typically used for SSA measurement, using either

nitrogen or krypton adsorption. Mercury Porosimetry is used for the full

characterisation of pore volume and pore size and is more informative

than SSA by gas adsorption data alone.

Key Techniques:

•

BET surface area (SSA) by nitrogen

•

BET surface area (SSA) by krypton for low area samples

•

Mercury Porosimetry for pore volume measurement

•

Mercury Porosimetry for pore size distribution

•

Mercury Porosimetry for volume (%) porosity measurement

•

Micropore analysis for pore volume, area and size measurement

•

Bulk (envelope) density measurement

•

Analysis of powder blends

•

Analysis of solid dosage forms

At MCA Services we offer a complete suite of techniques for the

characterisation of sample porosity with the experience and expertise to

actively assist with the interpretation of results and their relation to

development and performance criteria. Our ongoing in-house research

continues to highlight the significance of and application of these analytical

techniques to the pharmaceutical sector.

01763262333

LATEST RESEARCH NEWS:

New research paper by MCA Services

BET surface area measurement of

commercial magnesium stearate by krypton

adsorption in preference to nitrogen

adsorption. International Journal of

Pharmaceutics. Volume 568, 10 September

2019.