Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End, Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

Analysis of Catalysts and Electro-catalyst Systems

The

significance

and

influence

of

the

porous

nature

of

catalyst

systems

with

respect

to

their

functionality,

performance

and

efficiency

is

well

known

as

is

the

importance

of

understanding

the

physicochemical

properties

of

the

active

constituents.

The

characterisation

of

the

porous

nature

of

catalysts

can

be

applied

to

the

active

constituents

and

supports

separately

or

to

the

finished

system.

These

principles

can

also

be

applied

to

electro-catalyst

systems

and

our

Battery

Materials

page

gives

more

details.

Investigations

of

physicochemical

properties

in

order

to

determine

activity

and

efficiency

can

also

be

applied

to

the

active

constituents

alone

or

to

the

finished

catalytic

system.

All

of

these

properties

can

not

only

be

applied

to

new

catalysts

but

also

to

used

and

regenerated

materials

as

part

of

investigations

into

their

degradation and regeneration efficiency.

Key Techniques.

•

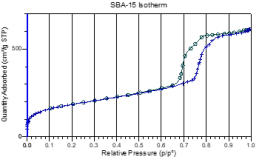

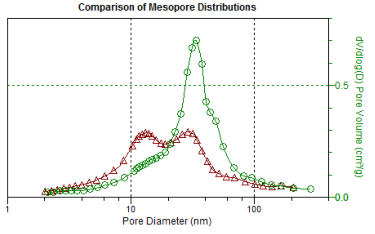

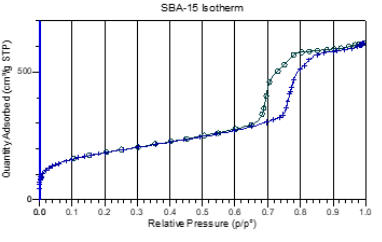

Gas Adsorption: pore size, area and volume determination in the mesopore

range.

•

Gas Adsorption: BET Surface Area.

•

Micropore Analysis: pore size, area and volume determination in the micropore

range.

•

Micropore Analysis: wide choice of adsorbate gases for ultra-micropore

characterisation.

•

Mercury Intrusion Porosimetry: pore size, area and volume determination in

meso & macropore ranges.

•

Mercury Intrusion / Extrusion Porosimetry: cavity to throat size

determination.

•

Chemisorption: active metal surface area and dispersion measurement.

•

Permeability and Tortuosity: measurement by mercury intrusion

porosimetry.

•

Temperature Programmed Methods: reduction, oxidation, adsorption &

desorption.

•

Density Measurement: absolute density, bulk (envelope) density and skeletal density.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

physical

characterisation

of

catalyst

systems.

Through

Mercury

porosimetry

and

gas

adsorption

with

micropore

analysis,

the

complete

range

of

pore

sizes,

from

micropores,

through

mesopores

and

into

macropores

can

be

characterised

for

volume,

area

and

pore

size

distributions.

The

complete

range

of

pore

sizes

which

can

be

measured

by

combination

of

these

techniques

is

in

the

order

of

3

nm

to

650

µm.

Gas

adsorption

options

usually

also

provide

the

BET

surface

area

of

the

sample

material

as

part

of the analysis. Mercury porosimetry options can be extended to include the measurement of permeability and pore tortuosity.

Whilst

nitrogen

is

traditionally

applied

to

gas

adsorption,

more

specialised

adsorbate

options

are

available

for

the

analysis

of

specific

sample

materials.

For

example,

characterisation

of

ultra-micropores

(<

1.0

nm)

in

carbon,

charcoal,

graphene,

CNTs

etc

can

be

analysed

by

carbon

dioxide

adsorption

whilst

argon

adsorption

is

preferred

when

analysing

zeolites,

MOFs

and

ZIFs.

Hydrogen,

oxygen

and

water

adsorption

options are also available as is the measurement of the isosteric heat of adsorption from hydrogen isosteres.

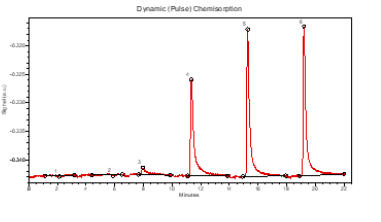

Chemisorption

(chemical

adsorption)

is

routinely

applied

to

the

analysis

of

a

ctive

metal

constituents

to

determine

their

availability

for

the

desired

catalytic

reaction.

The

active

metal

surface

area

and

active

metal

dispersion

are

most

commonly

applied

to

this.

At

MCA

Services

we

offer

chemisorption

by

static

volumetric

and

dynamic

(pulse)

techniques

and

the

provision

of

a

range

of

sorptive

gases

means

that

a

wide

range

of

active

metals

of

varying

loading

can

be

analysed.

Hydrogen

and

carbon

monoxide

chemisorption

represent

the

most

common

methods

but

other sorptive gases are available, such as ammonia and oxygen.

We

have

extensive

experience

in

the

field

of

catalysis

and

the

expertise

to

assist

with

the

interpretation

of

results

to

gain

the

maximum

insight

into

the

materials

analysed.

Benefits

are

extended

through

the

application

of

state-of-the-art instrumentation and software which provide the highest quality results together with specialised reporting options.

Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End,

Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

Analysis of Catalysts and Electro-catalyst Systems

The

significance

and

influence

of

the

porous

nature

of

catalyst

systems

with

respect

to

their

functionality,

performance

and

efficiency

is

well

known

as

is

the

importance

of

understanding

the

physicochemical

properties

of

the

active

constituents.

The

characterisation

of

the

porous

nature

of

catalysts

can

be

applied

to

the

active

constituents

and

supports

separately

or

to

the

finished

system.

These

principles

can

also

be

applied

to

electro-catalyst

systems

and

our

Battery

Materials

page

gives

more

details.

Investigations

of

physicochemical

properties

in

order

to

determine

activity

and

efficiency

can

also

be

applied

to

the

active

constituents

alone

or

to

the

finished

catalytic

system.

All

of

these

properties

can

not

only

be

applied

to

new

catalysts

but

also

to

used

and

regenerated

materials

as

part

of

investigations

into

their

degradation

and

regeneration efficiency.

Key Techniques.

Gas Adsorption: pore size, area and volume determination in the

mesopore range.

Gas Adsorption: BET Surface Area.

Micropore Analysis: pore size, area and volume determination in the

micropore range.

Micropore Analysis: wide choice of adsorbate gases for ultra-

micropore characterisation.

Mercury Intrusion Porosimetry: pore size, area and volume

determination in meso & macropore ranges.

Mercury Intrusion / Extrusion

Porosimetry: cavity to throat

size determination.

Chemisorption: active metal

surface area and dispersion

measurement.

Permeability and Tortuosity:

measurement by mercury intrusion porosimetry.

Temperature Programmed Methods: reduction, oxidation, adsorption

& desorption.

Density Measurement: absolute density, bulk (envelope) density and

skeletal density.

MCA

Services

offers

a

complete

suite

of

techniques

for

the

physical

characterisation

of

catalyst

systems.

Through

Mercury

porosimetry

and

gas

adsorption

with

micropore

analysis,

the

complete

range

of

pore

sizes,

from

micropores,

through

mesopores

and

into

macropores

can

be

characterised

for

volume,

area

and

pore

size

distributions.

The

complete

range

of

pore

sizes

which

can

be

measured

by

combination

of

these

techniques

is

in

the

order

of

3

nm

to

650

µm.

Gas

adsorption

options

usually

also

provide

the

BET

surface

area

of

the

sample

material

as

part

of

the

analysis.

Mercury

porosimetry

options

can

be

extended

to

include

the

measurement

of

permeability

and

pore

tortuosity.

Whilst

nitrogen

is

traditionally

applied

to

gas

adsorption,

more

specialised

adsorbate

options

are

available

for

the

analysis

of

specific

sample

materials.

For

example,

characterisation

of

ultra-micropores

(<

1.0

nm)

in

carbon,

charcoal,

graphene,

CNTs

etc

can

be

analysed

by

carbon

dioxide

adsorption

whilst

argon

adsorption

is

preferred

when

analysing

zeolites,

MOFs

and

ZIFs.

Hydrogen,

oxygen

and

water

adsorption

options

are

also

available

as

is

the

measurement

of

the

isosteric heat of adsorption from hydrogen isosteres.

Chemisorption

(chemical

adsorption)

is

routinely

applied

to

the

analysis

of

active

metal

constituents

to

determine

their

availability

for

the

desired

catalytic

reaction.

The

active

metal

surface

area

and

active

metal

dispersion

are

most

commonly

applied

to

this.

At

MCA

Services

we

offer

chemisorption

by

static

volumetric

and

dynamic

(pulse)

techniques

and

the

provision

of

a

range

of

sorptive

gases

means

that

a

wide

range

of

active

metals

of

varying

loading

can

be

analysed.

Hydrogen

and

carbon

monoxide

chemisorption

represent

the

most

common

methods

but

other

sorptive

gases

are

available,

such

as

amm

onia and oxygen.

We

have

extensive

experience

in

the

field

of

catalysis

and

the

expertise

to

assist

with

the

interpretation

of

results

to

gain

the

maximum

insight

into

the

materials

analysed.

Benefits

are

extended

through

the

application

of

state-of-the-art

instrumentation

and

software

which

provide

the

highest

quality

results

together

with

specialised reporting options.

01763262333