Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End, Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

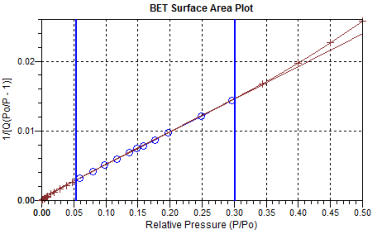

BET Surface Area by Nitrogen and Krypton Adsorption

The surface area of a material will often profoundly effect its behaviour and performance, whatever its application, and will commonly be a

critical parameter to consider when preparing or procuring a material. For example, surface area can be used to directly determine factors

such as reactivity, adsorption capacity, dissolution rate, electrochemical performance and burning / sintering ability. Knowledge and control

of surface area is often crucial at all stages of formulation, manufacture and ongoing QC processes.

Surface area, also termed Specific Surface Area (SSA), is most commonly measured by the BET (Brunauer-Emmett-Teller) method through

the gas adsorption technique. For the majority of samples nitrogen adsorption is used, but for very low surface area materials a krypton

adsorption option is also available.

Key Information

•

Surface area is a critical parameter for formulation, production and

performance.

•

Surface area often affects material performance

•

Surface area is often critical to material selection

•

BET Surface Area by Nitrogen adsorption

•

BET Surface area by Krypton adsorption for low area materials

•

Comprehensive degassing options available to suit specific requirements

•

Volumetric technique using state-of-the-art Micromeritics TriStar II 3020

•

Single point and multipoint measurement options available

•

Flowing gas method available where required

•

Argon adsorption option available

•

Carbon dioxide and oxygen adsorption options available

Sample

degassing

and

drying

immediately

prior

to

analysis

is

critical

to

ensure

that

samples

are

clean

and

dry.

This

is

undertaken

by

MCA

and

a

range

of

options

are

available,

including

vacuum

and

flowing

gas

techniques

at

temperatures

from

ambient

to

400

°C

are

available

to

ensure that samples are fully degassed without thermal degradation.

Nitrogen

adsorption

is

applicable

to

the

majority

of

sample

types.

However,

as

surface

area

becomes

particularly

low

nitrogen

fails

to

provide

accurate

data

from

which

to

calculate

surface

area.

In

such

cases

a

krypton

adsorption

option

is

also

offered

which

is

capable

of

measuring the geometric area of essentially non-porous materials.

Analyses

are

usually

undertaken

using

the

most

recent

Micromeritics

TriStar

3020

instrument,

offering

a

multipoint

volumetric

technique.

However,

a

flowing

gas

technique

and

single

point

measurement

options

are

also

available

which

provide

options

to

match

historical

methods and data.

Expertise in the Physical

Characterisation of Materials

MCA Services

Unit 1A Long Barn, North End,

Meldreth, Cambridgeshire SG8 6NT UK

01763 262333

© MCA Services

BET Surface Area by Nitrogen and Krypton Adsorption

The

surface

area

of

a

material

will

often

profoundly

effect

its

behaviour

and

performance,

whatever

its

application,

and

will

commonly

be

a

critical

parameter

to

consider

when

preparing

or

procuring

a

material.

For

example,

surface

area

can

be

used

to

directly

determine

factors

such

as

reactivity,

adsorption

capacity,

dissolution

rate,

electrochemical

performance

and

burning

/

sintering

ability.

Knowledge

and

control

of

surface

area

is

often

crucial

at

all

stages of formulation, manufacture and ongoing QC processes.

Surface

area,

also

termed

Specific

Surface

Area

(SSA),

is

most

commonly

measured

by

the

BET

(Brunauer-Emmett-Teller)

method

through

the

gas

adsorption

technique.

For

the

majority

of

samples

nitrogen

adsorption

is

used,

but

for

very

low

surface

area

materials

a

krypton adsorption option is also available.

Key Information

•

Surface area is a critical parameter for formulation, production

and performance

•

Surface area often affects material performance

•

Surface area is often critical to material selection

•

BET Surface Area by Nitrogen adsorption

•

BET Surface area by Krypton adsorption for low area materials

•

Comprehensive degassing options available to suit specific

requirements

•

Volumetric technique using state-of-the-art Micromeritics TriStar

II 3020

•

Single point and multipoint measurement options available

•

Flowing gas method available where required

•

Argon and Oxygen adsorption options available

•

Carbon dioxide adsorption available

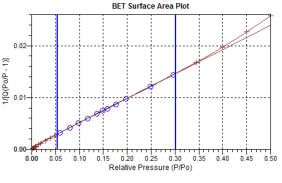

Sample degassing and drying immediately prior to analysis is critical

to ensure that samples are clean and dry. This is undertaken by MCA

and a range of options are available, including vacuum and flowing

gas techniques at temperatures from ambient to 400 °C re available

to ensure that samples are fully degassed without thermal

degradation.

Nitrogen adsorption is applicable to the majority of sample types.

However, as surface area becomes particularly low nitrogen fails to

provide accurate data from which to calculate surface area. In such

cases a krypton adsorption option is also offered which is capable of

measuring the geometric area of essentially non-porous materials.

Analyses are usually undertaken using the most recent Micromeritics

TriStar 3020 instrument, offering a multipoint volumetric technique.

However, a flowing gas technique and single point measurement

options are also available which provide options to match historical

methods and data.

01763262333